Transporting a sheet of paper with freshly printed wet ink without marking or smearing the wet ink,

has been a challenge for printers since the day of Gutenberg.

As sheetfed offset printing presses progressed to more colours and much higher speeds, marking became even more challenging. An anti-marking solution had to be found.

Since the 1970s many companies have developed solutions to offer a wide variety of anti-marking materials for several different reasons: performance, longevity, application requirements and price.

Choosing a material can be difficult when you consider all the options on offer. That’s why we’ve put together a buying guide to to help you choose the correct material for your press.

This decision can be made even more difficult when your budget is being stretched. But we're here to help!

Budget Options Full Ranking

Kitting out your transfer cylinders is just like buying tyres, you should buy the best you can afford.

When the budget is lean and you just need something to get by, here's what we recommend:

- ICP Film

- Super Blue 2 Nets

- Economy+ Jackets

- Anti-Marking Paper

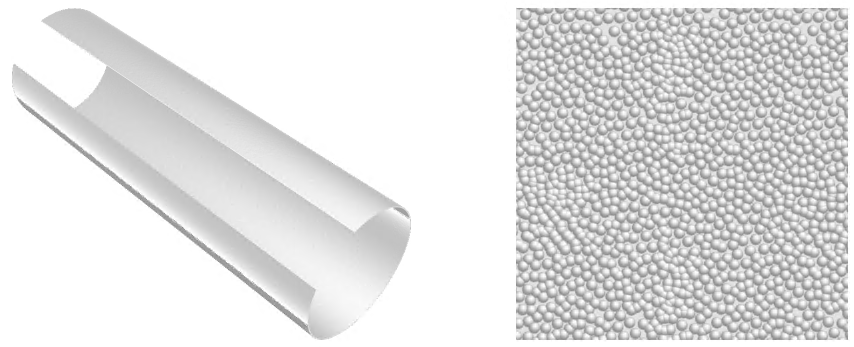

ICP Film

The standard performance anti-marking film developed by the original glass bead manufacturers,

Shinoda. Available in Large or Small bead size to suit different paper/card stocks.

The silicone glass beads are protected with a single, uniform, coating to seal and protect them in

a dense matrix. Resistant to ink and oil to help the repelling process and reduce ink build up on

cylinder. Available with and without adhesive backing.

Reasons to Buy

- Two bead sizes available (Large or Small)

- Low cost sheets

- Adhesive film to suit installation preference

Reasons to Avoid

- Not as high performance as the premium films

| Price |

Production |

Performance |

| ££ £££ - Low |

★★★★★ - Best |

★★★☆☆ - Good |

Super Blue 2 Nets

The original anti-marking net from Printing Research Inc. Used worldwide by printers for decades

as the no-clean anti marking system. Fitted as standard by most original manufacturers.

Reasons to Buy

- No cleaning required

- Available for all press makes and models

- Award winning technology

Reasons to Avoid

- Change more frequently than film sheets or jackets

- Potentially additional Base Cover costs

| Price |

Production |

Performance |

| ££ £££ - Low |

★★★★★ - Best |

★★★★☆ - Great |

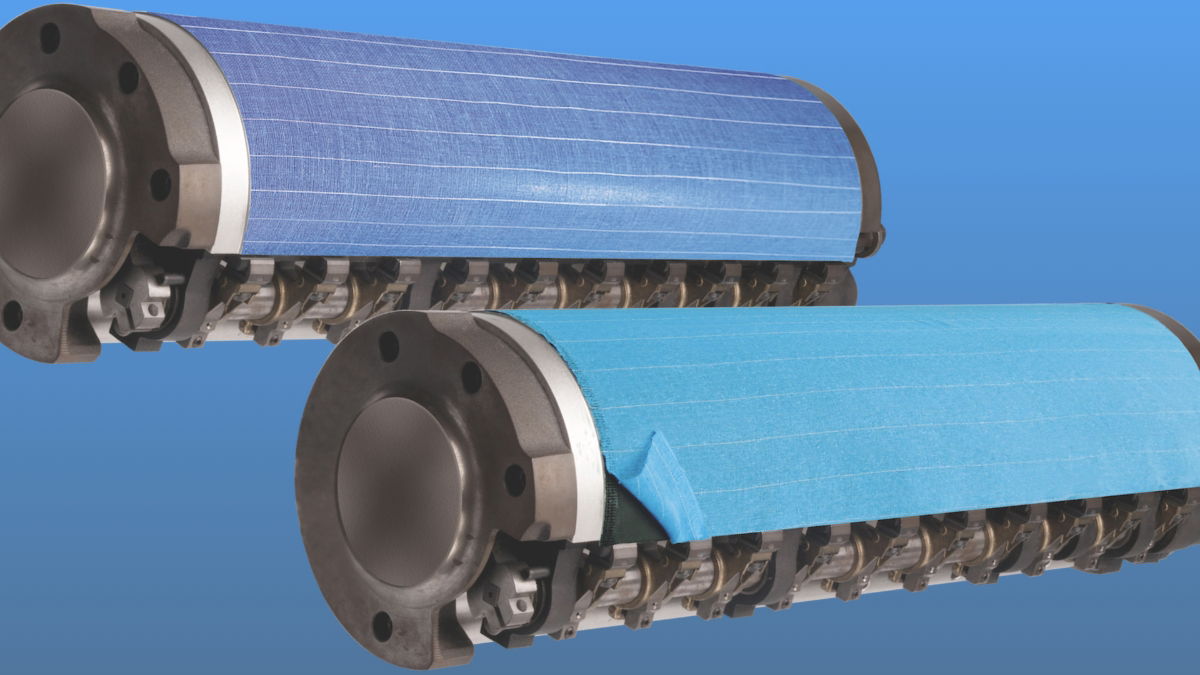

Economy+ Jackets

Standard white anti-marking film converted into jackets for Heidelberg transfer cylinder.

Made exclusively for Bluprint UK.

Reasons to Buy

- Easy install

- More durable than film sheets

- Relatively low cost

Reasons to Avoid

- Heidelberg Only

- Less ink resistant than premium jackets

| Price |

Production |

Performance |

| £££ ££ - Mid |

★★★★★ - Best |

★★★☆☆ - Good |

Anti-Marking Paper

Oil impregnated anti-marking paper offers the most economical solution to marking problems.

Reasons to Buy

Reasons to Avoid

- Beads readily come away without coating to keep them on

- Cannot be cleaned

| Price |

Production |

Performance |

| £ ££££ - Lowest |

★★☆☆☆ - Ok |

★★☆☆☆ - Ok |

If you are still unsure which is best for you, please contact us directly to discuss your specific

requirements and preferences.

You can read the full Anti-Marking Buyers Guide here.